Climate impact

Energy efficient combined heat and power (CHP) production covers almost 80% of industrial heat in Finland – a much higher share than in other countries. In Denmark and Finland most buildings in urban areas are covered with district heating and about 70–80% of this heat is produced with CHP.

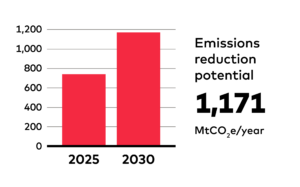

In the case of industrial heat, we have analysed the potential of scaling up Finnish shares of CHP globally in four industries: pulp and paper, chemicals, food and wood products. This would result in emissions savings of 292 Mt in 2030.

In the case of buildings, we have applied the Danish and Finnish shares of district heating with CHP to urban areas in OECD countries, many of which have cold or temperate climates. Scaling up the solution would cut emissions by as much as 879 Mt in 2030.

Success factors

Key enablers for CHP and district heating are the incentives for the necessary infrastructure. Building a district heating network is much cheaper, if developers work together with urban planners to coordinate the construction of heating networks, CHP plants and buildings.

Finland has supported CHP production with fuel tax exemptions. Local governments have the authority to require buildings to join a district heating network.

Also in Denmark the local government can mandate connecting households to district heating. A support scheme subsidises the installation cost when swapping from other energy sources (oil and natural gas).

“Finland covers 4/5 of heat in

industry and district heating

with combined heat and

power production.”

Costs

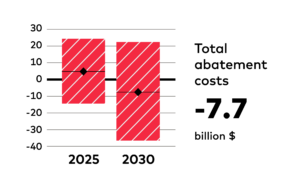

A weighted average cost for both retrofits and new-builds in industrial CHP is –6.6 $/tCO2, thanks to fuel savings. Scaling up the solution would have a total negative cost of–$1.9 billion in 2030.

Retrofitting existing buildings so that the full cost of the CHP and district heating system applies is very expensive at around 260 $/tCO2 in 2030. Taking also into account the lower cost when building CHP and district heating at the same time as a new building is constructed or an old one is refurbished, the lower construction cost combined with savings from lower fuel consumption results in a net saving of –7 $/tCO2 in 2030.

This would result in estimated total net costs for both industrial and district heating CHP of–$8 billion in 2030. Cost estimates have a large range, however, depending on assumptions about the rate of new construction and replacements, for example.

Co-benefits

CHP provides several co-benefits compared with the separate production of heat and power. These include

- cutting harmful air pollution

- reducing fuel imports

- improving energy security

Barriers and drivers

Both industrial CHP and district heating networks are capital intensive and can have a relatively long payback time. This is particularly the case if interest rates are high or energy prices are low. In buildings where the owners and builders do not pay the energy costs themselves, there is little incentive to invest more to save on energy costs. Energy taxation and emissions trading can improve the attractiveness of CHP by increasing the cost of wasting energy.

Improving energy efficiency and increasing the share of distributed energy production (e.g. solar collectors and heat pumps) reduce the potential for CHP. Such measures also undermine the economics of district heating, since they imply less heat being sold without a corresponding reduction in capital costs.

RELATED SOLUTIONS