Climate impact

Between 2000 and 2010, Norwegian oil and gas production has reduced its methane emission intensity by 2.3% per year on an average. According to official statistics the level is only 2.8 kgCH4/TJ which is exceptionally low by international standards.

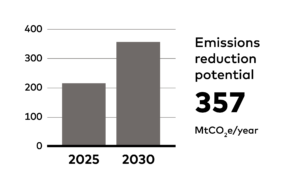

Other relatively developed and significant oil- and gas-producing countries without considerable programmes to cut upstream emissions can probably achieve the same annual reduction in methane intensity. Replicating the Norwegian improvement would cut global emissions by 357 MtCO2e in 2030.

Success factors

Methane (CH4) is the main component of natural gas. It is also a potent greenhouse gas, with a global warming potential 30–36 times that of carbon dioxide over a 100-year period.

Methane is released both intentionally and unintentionally as part of oil and gas extraction, as so-called fugitive emissions. Most intentionally released methane is burnt on release (flaring) in case the production site is too far away from a major demand centre to make selling the gas attractive.

Norwegian oil and gas production is reported to have the lowest methane intensity of any major oil- or gas-producing country. The country has also seen a steady decline in methane intensity over the past decade greater than the global average rate of improvement.

According to the industry itself, success is not primarily the result of a focus on reducing methane leakages, but rather due to strict safety regulations and high-quality equipment. All oil and gas production in Norway also takes place offshore, which requires greater attention to pipe sealing and equipment durability than onshore production.

“Safety regulations and quality equipment have cut emissions from the oil and gas industry in Norway.”

Costs

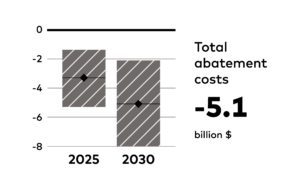

We have estimated the solution to cost approximately –15 $/tCO2 in 2030 as the reclaimed methane can be sold to the market. The total savings would then be –$5.1 billion in 2030.

Co-benefits

Reducing methane emissions in oil and gas production provides mainly climate and economic benefits. However, better designs and materials, increased maintenance and inspection may also relate to some co-benefits, in particular

- better safety and employee health

- higher productivity

Barriers and drivers

Reducing methane emissions from oil and gas production usually saves money when accounting for the value of the recovered gas. However, if that gas cannot be transported to potential customers, it does not necessarily have a value. Building pipelines or infrastructure for gas liquefaction and transport can solve the problem, although investment costs tend to be relatively high.

The oil and gas industry is used to high financial returns. Relatively low returns on methane abatement measures may not be attractive enough without further incentives or regulation, such as minimum requirements for emission intensity and the monitoring of leakage.

Until recently, there has been relatively little focus on reducing methane leakage. Government programmes, like the Natural Gas STAR in the United States, can help increase awareness and implementation.

RELATED SOLUTIONS