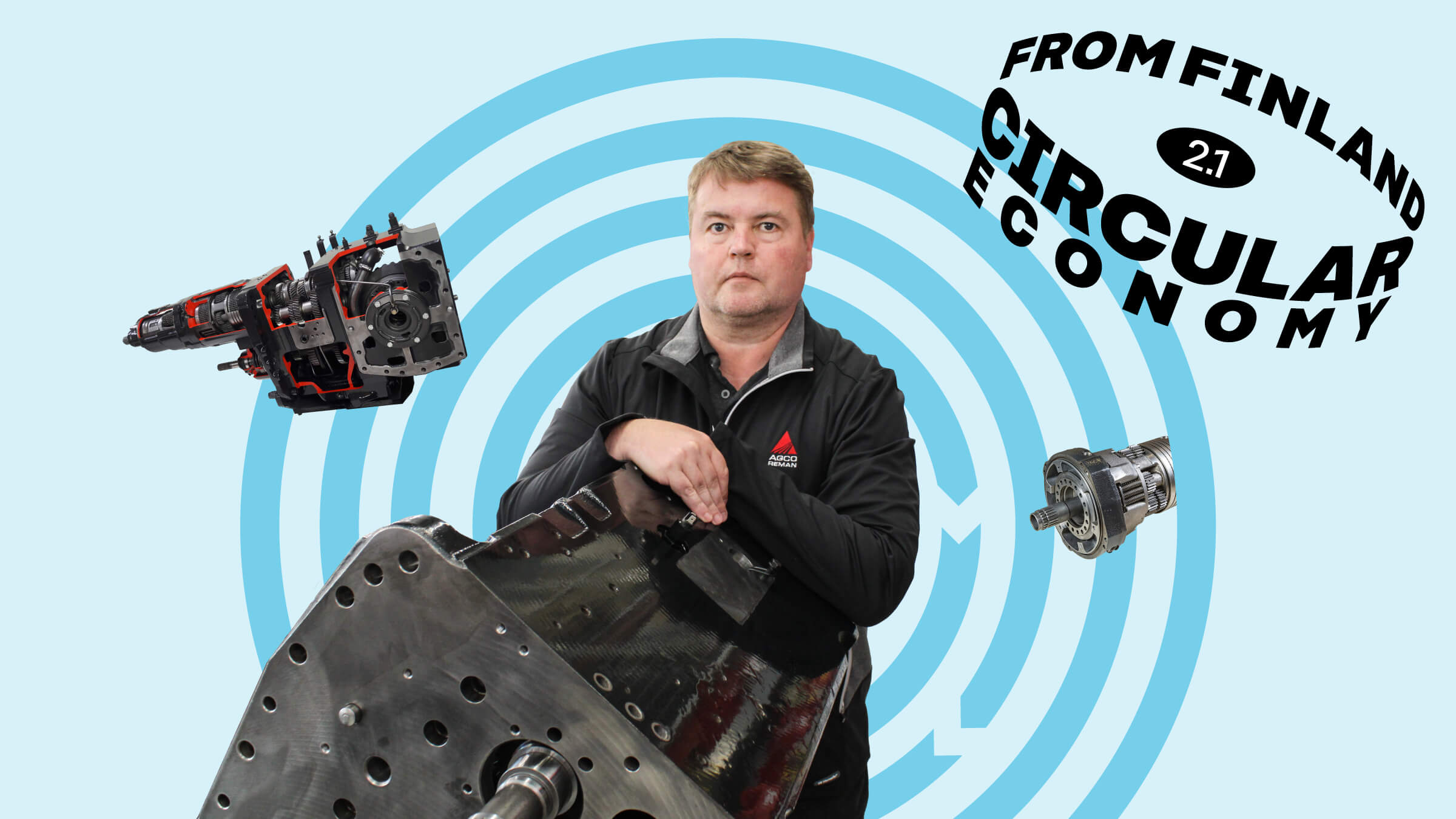

“In 2012, my supervisor and I were considering new ideas for developing Valtra’s maintenance services and the range of the services offered. Valtra’s factory at Suolahti has the best expertise in the world in the power transmission designed and manufactured by the company. One of its parts is the gear system. I suggested that we should begin to recondition the gear systems of our products for reuse. This would extend the service life of tractors.

The idea raised eyebrows at first, but I was allowed to proceed with our plans. In the beginning, I was given a space of one hundred square metres in a corner of the factory in Suolahti and a power transmission technician to work with.

This is how the Reman business for the gearboxes of Valtra tractors was launched. Reman is short for remanufacturing. If the gear system of the tractor is damaged, the owner can order a new gear system remanufactured from used parts, in other words, a Reman part. When the customer orders one from our warehouse, they pay a deposit in addition to the product price.

A service location authorised by Valtra replaces the tractor’s damaged gear system with the remanufactured part. Upon the return of the original damaged component to us, the deposit is paid back to the customer. The deposit is approximately half of the price of the gearbox and it ensures that we get the original component for remanufacturing. The popularity of the Reman service has grown steadily since 2012 and people seem to be more and more interested in it.

We offer remanufactured parts for tractors up to 30 years old, which have a history of tens of thousands of working hours. If the parts of the gear system, such as the box, have not been damaged, we can extend the service life by up to another 30 years. Our Reman parts have extended the lifespan of hundreds of machines in Europe.

Remanufacturing is a quick, cost-efficient and environmentally friendly way to service a tractor. Because the entire gearbox is replaced at the same time, our customer and maintenance personnel do not need to calculate what repairing individual parts will cost. Our maintenance personnel can also tell precisely how long it will take to replace the component. This way, we can give the customer an accurate cost estimate and the maintenance personnel can plan the timetables for the workshop better. The service carried out using a Reman part has a warranty of 12 months, the same as the warranty for a new part.

The customer saves both time and money – and the environment! We estimate that replacement parts save approximately 85 per cent of the energy and material compared to manufacturing a new part.”

Suosittelemme

Vielä yksi