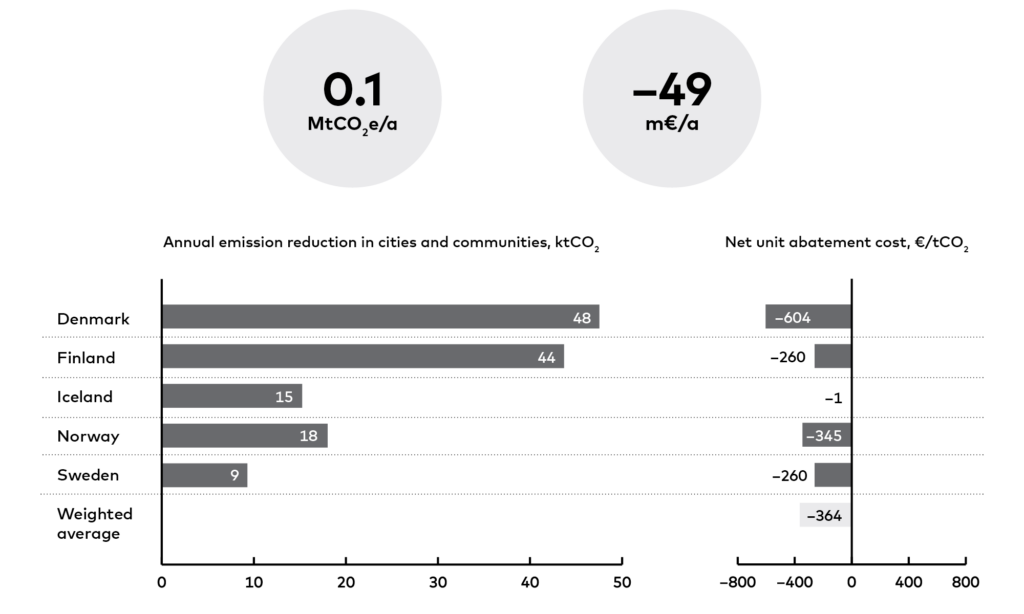

Climate impact

In Oslo, households pre-sort their food waste into green bags, which are separated from other waste at an automated waste-sorting plant and sent to a biogas plant. There, the food waste is anaerobically digested and turned into biogas, which is then used to fuel the waste collection trucks and city buses.

Each tonne of biowaste treated at Oslo’s plant produces around 900 kWh of liquid biomethane, which we estimate to replace around 80 litres of diesel as a transport fuel. We assume the biogas to be carbon neutral compared to the direct diesel emissions. Thereby, biogas reduces emissions by 180 kgCO2 per tonne of digested biowaste. If all Nordic municipalities turned 45% of their household food waste into transport biogas instead of composting, incinerating or landfilling it, we estimate it would reduce emissions by 134 ktCO2e.

Costs and savings

The production of biogas is a very cost-efficient way to treat biowaste because of the significant income generated through the sale of biogas. After sales of the end product, we estimate the total treatment cost per tonne of biowaste to be 43 €/t for composting, 105 €/t for incineration, –3 €/t for landfilling with gas capture and transport-fuel upgrade and –4€/t for biogas production. We estimate the the weighted average abatement cost to be –364 €/tCO2.

Other benefits

Biogas as a transport fuel reduces noise and air pollutants, such as nitrogen oxides and particulates.

The production of biogas also leaves behind digestate, which can be processed into fertilisers. The use of recycled fertilisers keeps important nutrients such as phosphorus, nitrogen and potassium circulating. It also reduces the need for virgin fertiliser production, which is emission-intensive as a result of energy requirements and the leakage of nitrous oxide during the production.

Barriers

- To produce biogas, biowaste needs to be separately sorted by households, which requires changes in behaviour.

- Overall, it only makes economic sense to invest in a biogas plant to treat the municipal biowaste if there is enough waste available. The solution may only be suitable for relatively densely populated areas and requires co-operation between neighbouring municipalities.

Enablers

- The landfilling of biowaste is banned by regulation in most Nordic countries, which often makes biogas production the cheapest option for treating it.

- The pre-sorting of food waste can be encouraged by education, providing opportunities for sorting at home and lowering biowaste fees relative to mixed waste.

- In Oslo, the coloured waste-sorting bags are available free of charge at supermarkets. All the bags go in the same bin, so there is no need to take the sorted waste to another location.

- Tax exemptions for biogas as a transport fuel improve its competitiveness. Biomethane plants in Norway are also eligible for investment grants.

RELATED SOLUTIONS