Climate impact

The US programme has cut annual energy use by an estimated 41 to 67 TWh. This results in an emission reduction of 28 to 47 Mt.

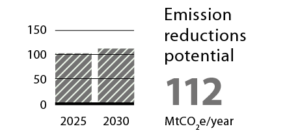

Electric motors are widely used in industries in all countries so the approach could be scaled up globally. This would reduce annual emissions by 85 to 139 Mt in 2030.

Success factors

The United States government applies minimum efficiency standards at the federal level. The rules cover mainly industrial electric motors both manufactured and imported for sale in the US.

The US Energy Independence and Security Act (EISA) assigns efficiency ratings according to motor type and size. The standards require manufacturers to certify their motor minimum efficiency values before they are allowed to sell their products.

Efficiency standards for electric motors are also used by other countries and promoted, for example, through the UNEP energy efficiency appliances programme. Other measures encouraging the uptake of energy-efficient motors include voluntary partnerships with industry, energy taxes and access to low-interest finance.

Costs

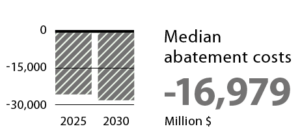

Improving the energy efficiency of electric motors cuts power consumption which saves money, delivering an estimated abatement cost of −200 to −72 $/tCO2e. Total savings from scaling up the solution globally would be $6 to $28 billion a year by 2030.

Co-benefits

Improving energy efficiency in industry reduces energy bills and improves competitiveness. It also reduces the need for imported fuel, improving energy security. As efficiency measures are more labour-intensive than power generation, improving efficiency can also create jobs.

Reducing energy demand also cuts air pollution from traditional power generation using fossil fuels. This in turn decreases harmful health impacts.

Barriers and drivers

- The barriers for implementing efficiency standards for electric motors are relatively low. The technology is established and widely available.

- Regulation can meet with scepticism from businesses. Involving different stakeholders in drafting rules, keeping them informed and highlighting benefits can address concerns.

- Good governance and administrative capacity is required to monitor and enforce standards. Conversely bad governance may mean slower adoption, especially in poorer countries.