Climate impact

China’s Top-10,000 programme covers two thirds of its industrial energy consumption. As a result, the energy efficiency of industry has improved on average by 3 to 4% annually.

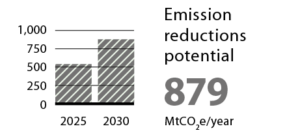

The Chinese approach could be scaled up to other countries with high industrial energy consumption. This would deliver annual emission reductions of 650 to 1,100 Mt by 2030.

Success factors

China introduced Top-10,000 in 2011 as an expansion of its successful predecessor, Top-1,000. Each set mandatory energy conservation targets for the country’s biggest energy users.

Under contracts signed with the government, participants in the programme are required to meet targets for energy savings. This involves various activities including conducting regular audits, setting up energy measurement and management systems and delivering energy conservation plans.

Other countries have used different tools to increase energy efficiency in industry. India’s Perform, Achieve and Trade programme allows businesses to trade energy savings in a similar way to trading carbon credits, for example.

Costs

The estimated abatement costs of improving energy efficiency in industry have a broad range, from savings of 15 $/tCO2e to costing 29 $/tCO2e. The total costs of scaling up this solution range from −$16 to $32 billion a year by 2030.

Co-benefits

Successful efficiency improvements reduce operational costs and improve competitiveness. They also reduce the need for fuel imports and improve energy security. As energy-efficiency measures are more labour-intensive than energy production, they can also create jobs.

Improving energy efficiency reduces air pollution and related health impacts. In China emissions from coal plants contribute to an estimated quarter of a million premature deaths in 2011.

Barriers and drivers

- Capacity to implement measures varies by region and company. In China, the government and third party service companies have provided capacity building and some companies have set up their own training systems.

- Energy conservation and upgrading of operations requires financial resources. In China, dedicated public funding and stimulated private investment have helped to enable this.

- Guidelines for industry and accounting methodology need to be clear. Targets should be independently verified and energy savings audited.

RELATED SOLUTIONS